In the fast-paced world of marketing and printing, ensuring the quality of your printed materials is crucial. A press check is a critical step in this process, allowing you to oversee the final production phase and ensure your printed materials meet your expectations. Whether you’re new to press checks or looking to refine your skills, this guide will walk you through the process and highlight the essential skills you need to conduct a successful press check.

What is a Press Check?

A press check is an on-site review of your printed materials at the printing press before the full production run begins. It’s your last opportunity to catch and correct any issues, ensuring that the final product aligns with your vision and specifications.

Preparing for a Press Check

Preparation is key to a successful press check. Here are the steps to take before you arrive at the printing press:

- Communicate with Your Printer: Ensure that you and your printer are on the same page regarding the schedule, expectations, and any specific concerns you have about the print job.

- Review the Proofs: Thoroughly review the digital and hardcopy proofs provided by the printer. Note any areas that need special attention or adjustments during the press check.

- Gather Your Materials: Bring all necessary materials with you, including color swatches, reference samples, and a detailed checklist of what you need to review during the press check.

- Know Your Specifications: Have a clear understanding of the paper stock, ink colors, coatings, and other specifications you’ve chosen for your project.

Conducting the Press Check

Once you’re at the printing press, follow these steps to ensure a thorough review:

- Arrive On Time: Punctuality is crucial. Arriving on time shows respect for the printer’s schedule and allows you to spend the necessary time reviewing the print job.

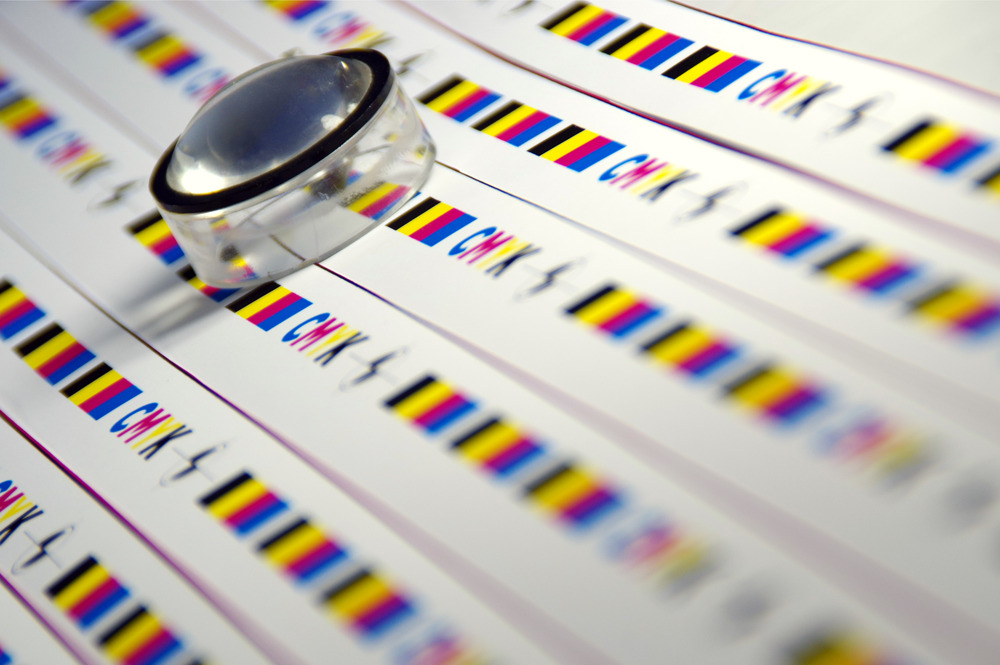

- Review the Setup Sheets: The printer will produce a few setup sheets for your review. Carefully examine these for color accuracy, registration, alignment, and overall quality.

- Check Color Consistency: Use your color swatches and reference samples to ensure that the colors are consistent and match your expectations. Be aware of any shifts in color that may occur due to lighting conditions in the pressroom.

- Inspect Details: Look for any issues with text, images, and graphics. Ensure that everything is sharp, clear, and properly aligned. Pay attention to areas with fine details or small text.

- Evaluate Paper and Finishing: Confirm that the paper stock and any coatings or finishes meet your specifications. Check for any issues with paper quality, such as scuffing, streaking, or curling.

- Communicate with the Printer: Discuss any concerns or adjustments with the printer. Be clear and specific about what needs to be changed and why.

- Approve or Reject the Print Job: Once you’re satisfied with the setup sheets, give your approval to proceed with the full production run. If there are issues that can’t be resolved on-site, you may need to reject the job and work with the printer to make necessary adjustments.

Essential Skills for Conducting a Press Check

Conducting a successful press check requires a combination of technical knowledge, attention to detail, and effective communication skills. Here are the key skills you need:

- Color Theory: Understanding color theory and how different colors interact is essential for evaluating color accuracy and consistency.

- Attention to Detail: A keen eye for detail allows you to catch even the smallest issues that could affect the quality of the final product.

- Technical Knowledge: Familiarity with printing processes, paper types, inks, and coatings helps you make informed decisions during the press check.

- Effective Communication: Clear and concise communication with the printer is crucial for addressing any issues and ensuring that your expectations are met.

- Problem-Solving: The ability to quickly identify and resolve issues on-site ensures that the press check process runs smoothly and efficiently.

- Time Management: Managing your time effectively allows you to thoroughly review the print job without causing delays in the production schedule.

Conclusion

A press check is a vital step in ensuring the quality of your printed materials. By preparing thoroughly, conducting a detailed review, and leveraging the essential skills outlined above, you can confidently approve your print job and achieve the best possible results. Remember, a successful press check not only saves time and money but also helps you deliver high-quality materials that reflect your brand’s professionalism and attention to detail.